Manufacturing Process

MANUFACTURING PROCESS

————————

|

|

||

|

EXTRUDING Statistical Quality Control is used to analyze and control the process to ensure that the quality of the filament meets our premium quality standard. |

|

|

TWISTING/ BRAIDING |

|

|

INSPECTION | |

|

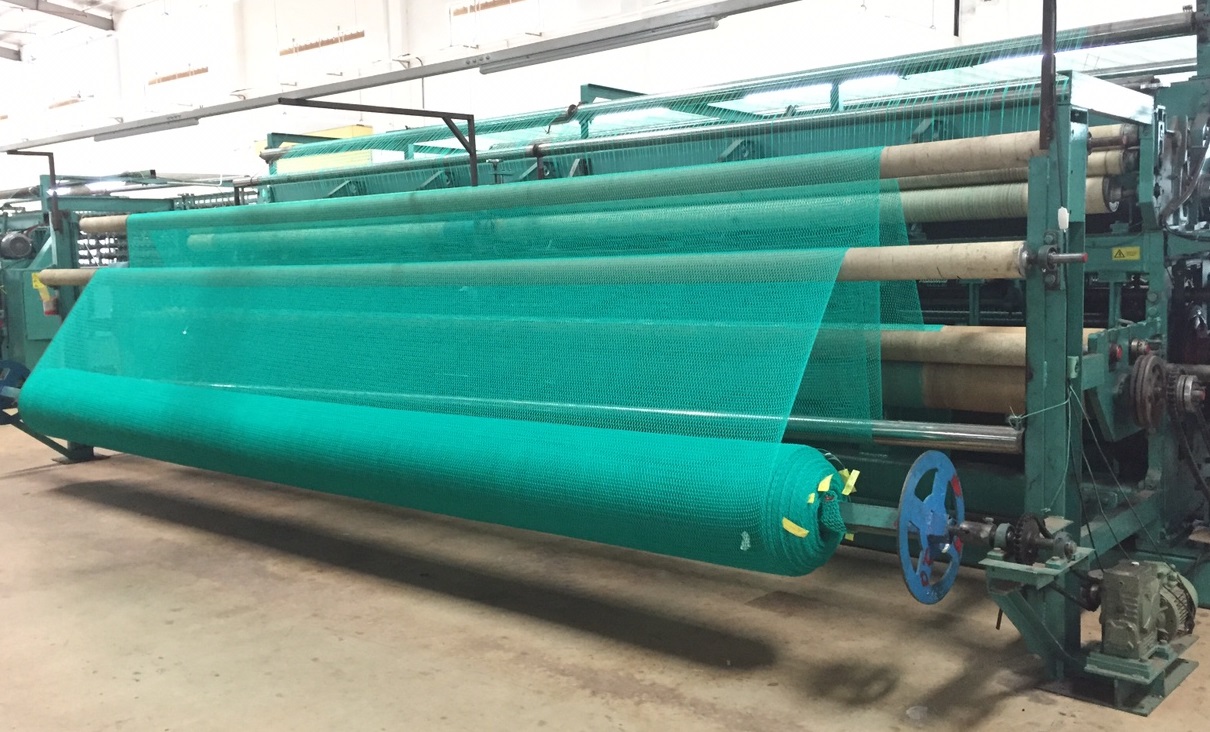

NET KNOTTING/ NET KNITTING |

|

|

At Forever Industries, quality is our primary concern. All of our products will be checked for the physical aspects such as diameter, mesh size, color, length, etc. Therefore, we can ensure that we will deliver only high-quality products to our customers. |

|

|

HEAT SETTING LENGTHWISE OR DEPTHWISE The nets will be stretched by Depthway or Lengthway through using steam and heat. |

||

|

INSPECTION | |

|

PACKAGING |